Your Vision

Our Technology

Manufacturing Technologies

Machining & CNC Milling

Sheet Metal & Stamping

Castings

Aluminum Extrusion, Forging & RHS

Plastic

Cable Assembly

One-Stop Shop

We specialize in providing comprehensive solutions while responding to every challenge in a variety of areas of activity, starting from the product designing and planning stage, through the use of advanced production technologies and ending with high level assembly into a finished product.

T.E-Metal focuses on the areas of activity of the defense industries, aviation, medicine, infrastructure and communication, vehicle, agriculture and more.

Our Process

Designing and Planning

One of our significant advantages is based on our ability to provide a fully planned and designed product for our customers, considering the best technologies and manufacturing methods to fulfill their needs.

T.E-Metal specializes in locating engineering problems and searching for solutions that best fit its customer's needs, sometimes by redesigning parts and components to achieve best solution as well as saving costs.

Our planning and designing methods are based on advanced software like: Bending-Trumpf, CncKad, Kitaron, SolidWorks, SolidCAM, etc.

Manufacturing

T.E-Metal provides manufacturing of metal and plastic parts and components in a variety of technologies, including CNC machining, electronic packaging, castings, Aluminum Extrusion and Forging and more.

We operate dozens of fully owned production machines in production centers throughout Asia, that allow us to manage and operate large projects at the same time and with high and uncompromising quality for our customers.

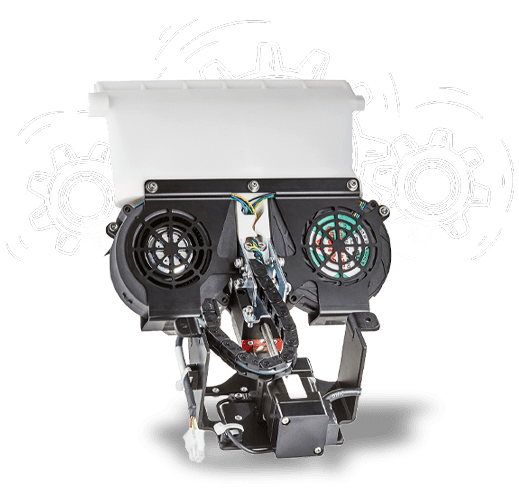

High-Level Assembly

T.E-Metal operates a turnkey method taking responsibility for the entire process, from design and procurement of materials to fabrication, assembly, and installation.

We often use this approach in large-scale projects, such as industrial facilities or infrastructure, where coordination between different subcontractors and suppliers can be challenging.

We are proud of our fully process providing our customers one-stop shop for planning, manufacturing, and mechanical assembly methods under the same roof.

Our Benefits

A production solution in all areas of metal, plastic and all types of technologies

One place for a complete end-to-end process - from planning, through production to assembly

A large number of production and assembly technologies under one roof

Engineers specializing in the field of metal for over 30 years

Reducing costs by adapting the work method and technology for each customer

Repairs, service and warranty are provided in one place

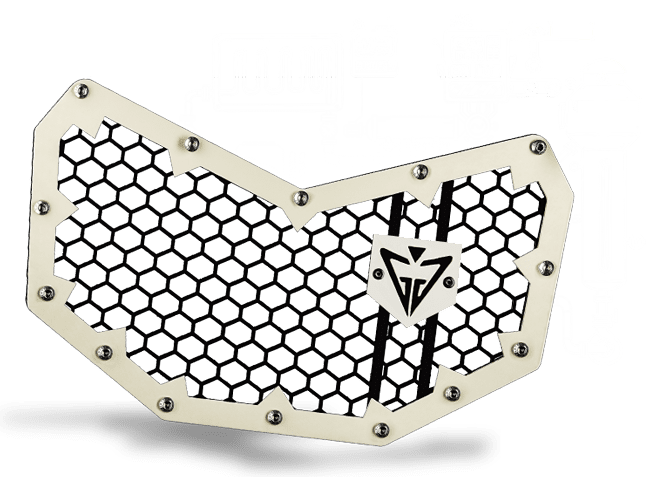

Our Products

T.E-Metal Worldwide

New York Manhattan - “Us Castings”

• Engineering

• QA

• Sales

• Logistics

• Assembly Department

Brasov, Romania - Production Factories

• CNC

• CNC Milling

Israel - “T.E-Metal”

• Engineering Manager

• NPI Department

• QA Manager

• Sales Manager

• Assembly Department

• Cable Assembly

China/Taiwan - Production Factories

• Shanghai – CNC & Milling

• Liaoning Province - AL Casting & CNC & Painting

• Hebei Province - Iron Casting & CNC & Coating

• Suzhou – Sheet metal & Paint & Coating & CNC

• Shenzhen- Plastic & Vacuum forming & 3D

Bangkok, Thailand - Production Factories

• CNC & Milling

• Sheet Metal

• Iron Casting

• AL Casting

• Metal Stamping

Izmir - Sheet Metal

• Cutting Laser

• Cutting Punch

• Bending

• Welding

• Paint

Our Clients

Reviews

Dear Eran, Tal and the TE METAL team,

On my behalf and on behalf of the Takia company and on behalf of Enercon Technologies I would like to thank you for the cooperation for many years and on a significant scale.

The professional support, uncompromising support, continuous quality, professionalism and personal attention in the supply of hundreds of thousands of items for leading security projects over many years - all of these made the joint activity a success and enabled compliance with the early delivery schedules while meeting the strict quality requirements that correspond to the requirements of the security industry.

On behalf of the Beewise company, thank you for your cooperation!

Beewise would like to thank T.E METAL for meeting production requirements in terms of quality and delivery times.

Thank you for the flexibility and production according to the company's requirements, supply of mechanical parts and complete assemblies with professional accompaniment and high quality and professional production including meeting delivery times